- An operating system is a program that controls the execution of application programs and acts as an interface between the user of a computer and the computer hardware.

- A more common definition is that the operating system is the one program running at all times on the computer (usually called the kernel), with all else being application programs.

- An operating system is concerned with the allocation of resources and services, such as memory, processors, devices, and information. The operating system correspondingly includes programs to manage these resources, such as a traffic controller, a scheduler, memory management module, I/O programs, and a file system.

- Convenience: An OS makes a computer more convenient to use.

- Efficiency: An OS allows the computer system resources to be used in an efficient manner.

- Ability to Evolve: An OS should be constructed in such a way as to permit the effective development, testing and introduction of new system functions at the same time without interfering with service.

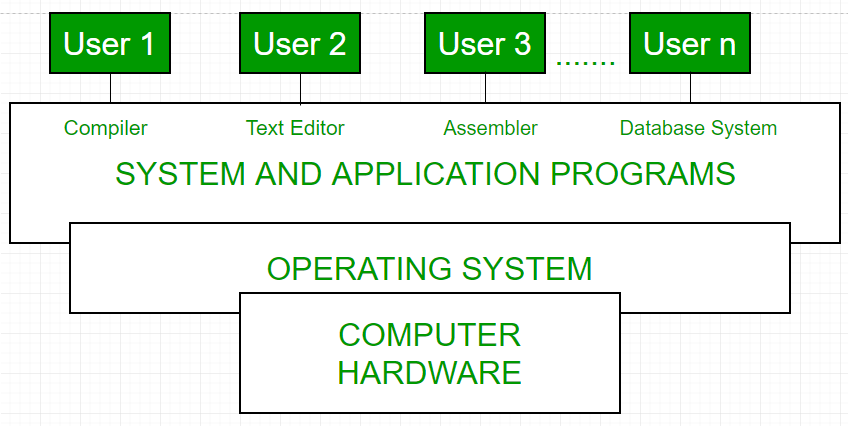

- User

- System and application programs

- Operating system

- Hardware

|

| Conceptual View of a Computer System |

Every computer must have an operating system to run other programs. The operating system coordinates the use of the hardware among the various system programs and application programs for various users. It simply provides an environment within which other programs can do useful work.

OS is designed to serve two basic purposes:

- It controls the allocation and use of the computing System’s resources among the various user and tasks.

- It provides an interface between the computer hardware and the programmer that simplifies and makes feasible for coding, creation, debugging of application programs.

- Provides the facilities to create, modification of programs and data files using an editor.

- Access to the compiler for translating the user program from high level language to machine language.

- Provide a loader program to move the compiled program code to the computer’s memory for execution.

- Provide routines that handle the details of I/O programming.

The module that keeps track of the status of devices is called the I/O traffic controller. Each I/O device has a device handler that resides in a separate process associated with that device.

The I/O subsystem consists of

- A memory Management component that includes buffering caching and spooling.

- A general device driver interface.

The input to an assembler is an assembly language program. The output is an object program plus information that enables the loader to prepare the object program for execution. At one time, the computer programmer had at his disposal a basic machine that interpreted, through hardware, certain fundamental instructions. He would program this computer by writing a series of ones and Zeros (Machine language), place them into the memory of the machine.

The High-level languages- examples are FORTRAN, COBOL, ALGOL and PL/I are processed by compilers and interpreters. A compiler is a program that accepts a source program in a “high-level language “and produces a corresponding object program. An interpreter is a program that appears to execute a source program as if it was machine language. The same name (FORTRAN, COBOL, etc.) is often used to designate both a compiler and its associated language.

A Loader is a routine that loads an object program and prepares it for execution. There are various loading schemes: absolute, relocating and direct-linking. In general, the loader must load, relocate and link the object program. The loader is a program that places programs into memory and prepares them for execution. In a simple loading scheme, the assembler outputs the machine language translation of a program on a secondary device and a loader places it in the core. The loader places into memory the machine language version of the user’s program and transfers control to it. Since the loader program is much smaller than the assembler, those make more core available to the user’s program.

Operating system has been evolving through the years. Following Table shows the history of OS.

| GENERATION | YEAR | ELECTRONIC DEVICE USED | TYPES OF OS DEVICE |

|---|---|---|---|

| First | 1945-55 | Vaccum Tubes | Plug Boards |

| Second | 1955-65 | Transistors | Batch Systems |

| Third | 1965-80 | Integrated Circuits(IC) | Multiprogramming |

| Fourth | Since 1980 | Large Scale Integration | PC |

- Batch Operating System- Sequence of jobs in a program on a computer without manual interventions.

- Time sharing operating System- allows many users to share the computer resources.(Max utilization of the resources).

- Distributed operating System- Manages a group of different computers and make appear to be a single computer.

- Network operating system- computers running in different operating system can participate in common network (It is used for security purpose).

- Real time operating system – meant applications to fix the deadlines.

- Windows (GUI based, PC)

- GNU/Linux (Personal, Workstations, ISP, File and print server, Three-tier client/Server)

- macOS (Macintosh), used for Apple’s personal computers and work stations (MacBook, iMac).

- Android (Google’s Operating System for smartphones/tablets/smartwatches)

- iOS (Apple’s OS for iPhone, iPad and iPod Touch)