The planer is a machine tool

designed to produce plane and flat surface on a workpiece which is too large or

too heavy. The workpiece is securely fixed on a table called platen, and it

reciprocates horizontally against a single edged cutting tool. The surface

machined may be horizontal, vertical or at an angle.

Operations of planer machine:

The planer is used for:

- Planing

flat horizontal, vertical and curved surfaces.

- Planing

at an angle and machining dovetails.

- Planing

slots and grooves.

The planer are available in

different types for doing different types and sizes of job; the most common

being the standard and double housing planer.

Construction

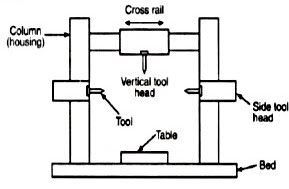

The main parts of the double

Housing Planer machine is Bed and table, Housings, Cross rail, Tool heads,

Driving and feed mechanism.

Bed

and table: The bed is a long heavy base and table made of cast iron.

Its top surface is flat and machine accurately. The flat top surface has slots

in which the workpiece can be securely clamped. The workpiece needs rigid

fixing so that it does not shift out of its position. The standard clamping

devices used on planer machine are: Heavy duty vice, T-holders and clamps,

angle plate, planer jack, step blocks and stop. The table movement may be

actuated by a variable speed drive through a rack and pinion arrangement, or a

hydraulic system.

Housings: The

housings are the rigid and upright column like castings. These are located near

the centre on each side of the base.

Cross

rail: The cross rail is a horizontal member supported on the

machined ways of the upright columns. Guide ways are provided on vertical face

of each column and that enables up and vertical movement of the cross rail. The

vertical movement of the cross rail allows to accommodate workpiece of

different heights. Since the cross rail is supported at both the ends, this

type of planer machine is rigid in construction.

Tool

heads: Generally two tool heads are mounted in the horizontal

cross rail and one on each of the vertical housing. Tool heads may be swiveled

so that angular cuts can be made. Driving and feed mechanism: The tool heads

may be fed either by hand or by power in crosswise or vertical direction. The

motor drive is usually at one side of the planer near the centre and drive

mechanism is located under the table. The size of the planer is specified by

the maximum length of the stroke, and also by the size of the largest

rectangular solid that can be machined on it.