The shaper is a machine tool

used primarily for:

- Producing

a flat or plane surface which may be in a horizontal, a vertical or an angular

plane.

- Making

slots, grooves and keyways

- Producing contour of concave/convex or a combination of these.

Working Principle

The job is rigidly fixed on

the machine table. The single point cutting tool held properly in the tool post

is mounted on a reciprocating ram. The reciprocating motion of the ram is

obtained by a quick return motion mechanism. As the ram reciprocates, the tool

cuts the material during its forward stroke. During return, there is no cutting

action and this stroke is called the idle stroke. The forward and return

strokes constitute one operating cycle of the shaper.

Construction

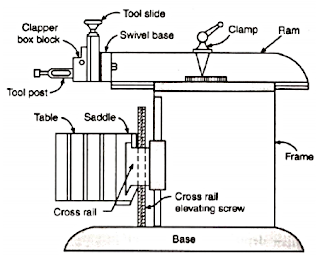

The main parts of the Shaper

machine is Base, Body (Pillar, Frame, Column), Cross rail, Ram and tool head

(Tool Post, Tool Slide, Clamper Box Block)

Base: The

base is a heavy cast iron casting which is fixed to the shop floor. It supports

the body frame and the entire load of the machine. The base absorbs and

withstands vibrations and other forces which are likely to be induced during

the shaping operations. Body (Pillar, Frame, Column): It is mounted on the base

and houses the drive mechanism compressing the main drives, the gear box and

the quick return mechanism for the ram movement. The top of the body provides

guide ways for the ram and its front provides the guide ways for the cross

rail.

Cross

rail: The cross rail is mounted on the front of the body frame

and can be moved up and down. The vertical movement of the cross rail permits

jobs of different heights to be accommodated below the tool. Sliding along the

cross rail is a saddle which carries the work table.

Ram

and tool head: The ram is driven back and forth in its

slides by the slotted link mechanism. The back and forth movement of ram is

called stroke and it can be adjusted according to the length of the workpiece

to be-machined.